|

Kumano Cho is located next to Higashihiroshima City. If you walk in Kumano Cho, you will find a lot of signs with the character “fude” (brush), as well as factories and houses that make brushes. Kumano Cho is known nationwide as Japan’s biggest producer of brushes.

| Why did the brush industry flourish in Kumano Cho? |  |

Reasons the brush industry flourished in Kumano Cho

|

About 170 years ago, Asano Han (modern-day Hiroshima Prefecture) encouraged crafts, so the sales of brushes and ink spread across Japan and young people in Kumano started to produce brushes.

Tameji Sasaki went to learn brush-making techniques in Arima (modern-day Hyogo Prefecture) upon the order of Chobei Sumiya, who sold brushes and ink. Jihei Inoue learned brush-making techniques from the Master of Brush who was invited by Saibe Magoita to serve Asano Han. Around the same time, Tsuneta Otomaru also learned brush-making techniques in Arima and returned to Kumano. These young men taught local people how to make brushes, and the brush-making techniques rooted in Kumano.

In the Meiji Period, more and more children began to go to school, increasing the demand for brushes. So, the production of Kumano Brushes increased. Brush producers worked hard to make better brushes. They started to produce paintbrushes and makeup brushes around 1955. Kumano Brushes became Hiroshima Prefecture’s first Traditional Craft designated by the Minister of International Trade and Industry in 1975.

As a result, Kumano Brushes became famous across Japan. Today, Kumano is the biggest seller of calligraphy brushes, paintbrushes, and makeup brushes in Japan.

Fude-no-sato Kobo is a facility that presents the brush-making tradition. You can learn about the history and process of brush-making in Kumano.

Fude-no-sato Kobo

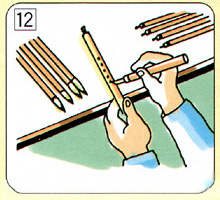

Various brushes |

Fude-no-sato Kobo exhibits different kinds of brushes such as calligraphy brushes, paintbrushes, and makeup brushes. There is also a brush larger than a person on display there.

Brushes are made of various kinds of hair.

| What kind of brushes are produced in Kumano Cho? Let’s find out what kind of hair is used in the brushes. |  |

Hair for calligraphy brushes (according to Kumanofude Cooperative)

Hair of raccoon dogs and weasels is also used.

| Main hair | Main origin | Reason for use and characteristics |

| Sheep wool | Japan, China | Relatively long with good-quality tip, sticky, and absorbs ink well.Used widely from luxury brushes to children’s brushes. |

| Horse hair | Japan, China, North America, South America | Soft and absorbs ink well.Blends well with other animal hair. |

| Deer hair | Japan | Elastic, used for the root core in the center for some techniques. |

Hair of raccoon dogs and weasels is also used.

| Taimo Fude, brushes made of hair from a baby’s first hair cut, are also produced. |

Kumano Cho sells 10 million writing brushes, 12 million paintbrushes, and 28 million makeup brushes annually in Japan and abroad. Most brushes are handmade by craftsmen.

| Let’s learn about the brush-making process and write it down. (Example) Making Kumano Brushes 1 Select and combine the hair. 2 Rub the hair. 3 Align the direction of the hair. |  |

Brush-making process

The brush-making process can be largely divided into 12 steps, consisting of over 70 small steps.

Brush-making

Kumano Brush-making

(Excerpt from “Kumano Brush” by Kumano Town Hall)

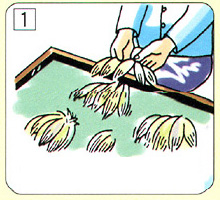

Choose and blend the hair according to the type of the brush. |

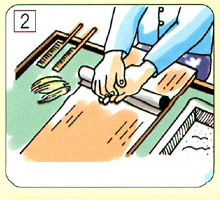

Sprinkle ashes over the hair, apply a hot iron, wrap the hair in deer leather and rub it. |

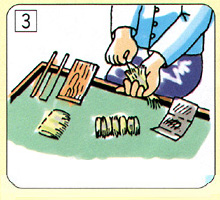

Take out loose hair, layer the hair, and align its direction. |

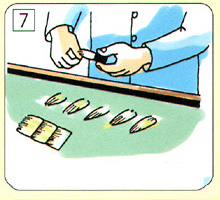

Take out the damaged hair and hair facing the wrong direction with a small knife. |

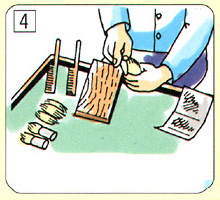

Cut the hair to length to each part, from the tip to the bottom. |

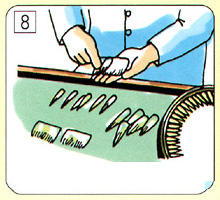

Spread the hair into a flat layer, fold and blend it, and apply a thin layer of glue. |

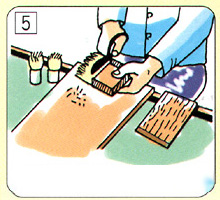

Shape the hair, insert it in the brush collar, and shape it into the appropriate size. |

Wrap the thin layer of top hair to the dried core. |

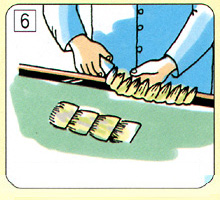

Tie the root with linen thread, sear it with hot iron, and the brush head is complete. |

Whittle the part of the brush handle where the brush head is inserted with a small knife, and glue the brush head in. |

Apply glue to the brush head, remove glue by turning the thread around, and adjust the shape. |

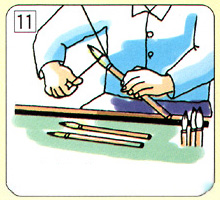

Engrave the name on the brush handle with a chisel. |

We interviewed the Master of Brush who is in charge of the brush hair. He is certified as a Traditional Craftsman.

Comment from the Master of Brush Comment from the Master of Brush |

| It takes at least 10 years to acquire the brush-making techniques. I have made a lot of brushes, but each one is different. I depend on my intuition, which I acquired over the years. For some kinds of hair, I have to find and pull out bad hair among tens of thousands of hairs. My eyes sometimes get very tired. Brush-making is very difficult and requires patience. Some craftsmen have been making brushes for 50 years, but they still learn new things every day. |

Trivia 【What is a Traditional Craft?】 Trivia 【What is a Traditional Craft?】 |

Traditional Craft logo |

| A Traditional Craft is a craft recognized by the Minister of Economy, Trade and Industry under the following conditions: 1 It must be used in everyday life. 2 The main part of the production process must be manual. 3 It must be produced with traditional technology or techniques (over 100 years old). 4 It must use traditional materials. 5 It must be produced in a particular area. People with long experience and excellent techniques of making Traditional Crafts are designated “Traditional Craftsmen” by the Minister of Economy, Trade and Industry. Kumano Brush was designated as a Traditional Craft on May 10, 1975. In Hiroshima Prefecture, Miyajima Woodwork, Hiroshima Buddhist altars, Fukuyama Japanese harps, and Kawajiri Brush are also designated as Traditional Crafts. Let’s look them up in books in the library. |